Plastic welding collision repairs require assessing damage like dents, cracks, and breaks, with technicians evaluating severity and location. For Mercedes-Benz repairs, expertise considers material, thickness, and integrity to select optimal strategies. Meticulous preparation clears damaged areas of debris and dust. Small cracks use heat-based welding; extensive damage employs structural repair techniques or advanced adhesives/mechanical fastening. Complex deformities involve inspection, shaping, application of weld material, and precise melting/fusing for durable autobody repairs.

In the realm of plastic welding, understanding various types of damage is crucial for effective collision repair. This article serves as a comprehensive guide, breaking down common plastic issues encountered post-collisions and detailing suitable welding repair techniques. From assessing cracks and chips to restoring complex deformities, we explore step-by-step processes ensuring optimal restoration. By arming professionals with this knowledge, plastic welding capabilities are enhanced, promoting quality outcomes in the face of automotive or product damage.

- Assessing Common Plastic Damage for Welding Repairs

- Techniques for Repairing Cracks and Chips

- Restoring Complex Deformities: A Step-by-Step Guide

Assessing Common Plastic Damage for Welding Repairs

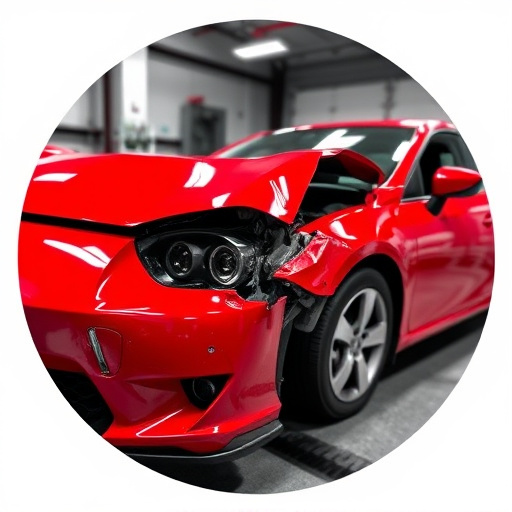

When it comes to plastic welding collision repairs, assessing the damage is a crucial first step. Common types of plastic damage include dents, cracks, and breaks, which can be caused by various incidents such as automotive collisions or accidental drops. To determine if welding is the suitable repair method, technicians need to consider the severity and location of the damage. For instance, minor dents and superficial cracks often respond well to dent removal techniques, whereas more intricate or structural damage may require complex repairs that involve plastic welding.

In the case of automotive collision repair, such as Mercedes-Benz repair, precision is key. Skilled technicians use their expertise to evaluate whether the damaged plastic component can be successfully restored through welding. This involves examining factors like material composition, thickness, and the overall structural integrity of the part. By carefully assessing these aspects, professionals can decide on the most effective strategy, ensuring a seamless and durable repair outcome that meets high-quality standards, even for premium vehicle brands like Mercedes-Benz.

Techniques for Repairing Cracks and Chips

When it comes to repairing cracks and chips in plastic components, especially after a collision or automotive incident, professional techniques are essential for achieving strong and lasting results. The process often involves careful preparation of the damaged area, ensuring it’s free from debris and dust. This meticulousness is crucial as any impurities can hinder the bonding strength during the repair.

Autobody repairs specialists employ various methods tailored to different types of plastic damage. For smaller cracks, a technique known as heat-based welding is commonly used. This involves heating the plastic with specialized tools, melting the edges of the crack, and then re-welding them together. For chips or larger damage, structural repair techniques are employed, where damaged sections are carefully removed, replaced, and fused using advanced adhesives or even mechanical fastening methods. These skills are vital in ensuring vehicle repair longevity and restoring the integrity of plastic components, maintaining their structural strength and aesthetic appeal.

Restoring Complex Deformities: A Step-by-Step Guide

Restoring Complex Deformities: A Step-by-Step Guide

When it comes to plastic welding collision repair, addressing complex deformities requires a meticulous approach. Start by thoroughly inspecting the damaged area, identifying all cracks, bends, and misalignments. Next, use specialized tools like air compressors and heat guns to carefully straighten and shape the plastic, bringing it back to its original form. This initial preparation ensures that the subsequent welding process will be more precise and effective.

In autobody repairs, precision is key. Once the plastic is shaped, apply a thin layer of plastic weld material, often an adhesive or fusion polymer, to the affected areas. Using heat sources like infrared heaters or hot air guns, carefully melt and fuse the plastic, creating a seamless bond. Maintain consistent pressure during the welding process to achieve strong, long-lasting autobody repairs. This step-by-step guide ensures that even the most intricate plastic deformities can be successfully restored in a collision repair shop, enhancing the overall quality of auto collision center services.

When it comes to repairing plastic damage via welding, understanding the various types of imperfections and employing the right techniques is key. From assessing cracks and chips to restoring complex deformities, this guide has equipped you with the knowledge needed for successful plastic welding repair. By recognizing common issues from collisions or other incidents and utilizing suitable methods, you can now effectively tackle a range of plastic damage cases. Remember, proper assessment and tailored techniques are essential for achieving robust and lasting repairs in the world of plastic welding.