Plastic welding is a specialized technique crucial for auto body repairs, creating strong, permanent bonds in bodywork using heat and pressure. Adhesive bonding offers a swift, cost-effective alternative, using chemicals to join parts with precision, suitable for diverse tasks from bumper repairs to glass replacement. The choice between these methods depends on repair complexity, material types, and desired durability, each having unique advantages and limitations in collision repairs.

In the realm of auto repairs, choosing the right method for restoring damaged plastic components is crucial. This article delves into two prominent techniques: plastic welding and adhesive bonding. While plastic welding offers precise joins for complex shapes in collision repair, adhesive bonding provides a fast, cost-effective alternative with its own strengths. We explore these methods’ unique features, advantages, and drawbacks to help professionals select the optimal approach for every repair scenario.

- Understanding Plastic Welding Techniques in Auto Repairs

- Adhesive Bonding: An Alternative Approach for Collision Repair

- Comparative Analysis: Strengths and Weaknesses of Both Methods

Understanding Plastic Welding Techniques in Auto Repairs

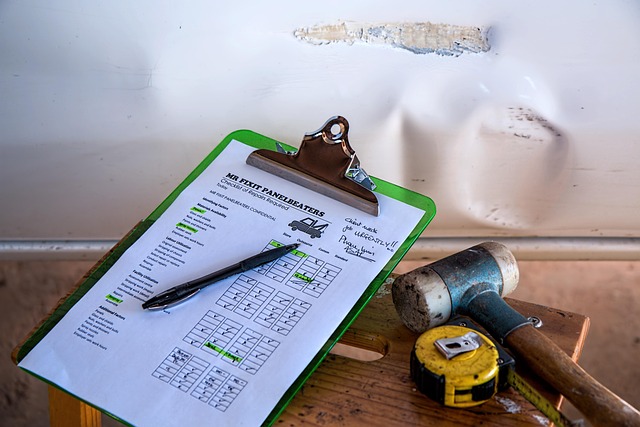

Plastic welding is a specialized technique used extensively in auto repairs, particularly for vehicle bodywork, to fuse and mend various plastic components. In the realm of collision repair, where every part of a vehicle needs meticulous attention, understanding this process is paramount. It involves precise application of heat and pressure to melt and fuse two or more plastic surfaces, creating a strong, permanent bond that’s virtually indistinguishable from the original material.

This technique is especially valuable for repairing or replacing parts like bumpers, fenders, and even interior panels, ensuring both structural integrity and aesthetic harmony in auto body services. Unlike traditional adhesive bonding, which may not hold up to the rigors of daily driving, plastic welding offers a durable solution, making it a go-to method for tire services and comprehensive vehicle bodywork repairs.

Adhesive Bonding: An Alternative Approach for Collision Repair

Adhesive bonding offers a compelling alternative to plastic welding for collision repairs. This method involves using specialized adhesives to join automotive components together, providing a strong and durable bond that can match or even exceed the strength of traditional welds. In bumper repair and other forms of automotive body work, adhesive bonding is particularly useful when dealing with intricate shapes and surfaces.

Unlike plastic welding, which can be time-consuming and requires specialized equipment, adhesive bonding is often faster and more cost-effective. It’s also advantageous in situations where access to hard-to-reach areas is necessary, as the adhesives can be applied precisely without the need for extensive heating or melting of materials. This makes it a versatile option for tasks ranging from auto glass replacement to intricate body panel repairs, ensuring that vehicles return to their pre-collision condition with minimal environmental impact.

Comparative Analysis: Strengths and Weaknesses of Both Methods

Plastic welding and adhesive bonding are both techniques employed in auto repairs, each with its unique advantages and drawbacks. When comparing these methods, understanding their strengths and weaknesses is crucial for choosing the most suitable approach for specific car dent repair or car body repair scenarios.

In terms of plastic welding, a collision repair expert uses heat to fuse two plastic parts together, creating a strong and permanent bond. This method excels in joining similar types of plastics, ensuring a seamless fusion that can withstand rigorous testing. However, it requires specialized equipment and trained technicians, making it costlier for car paint repair processes compared to adhesive bonding. Plastic welding is also more challenging when dealing with intricate or complex geometric shapes, as the heat application must be precise to avoid damaging the surrounding areas. On the other hand, adhesive bonding uses strong chemicals to attach materials, offering a cost-effective solution for various car body repair needs. It provides excellent flexibility in terms of bonding different substrates and is particularly useful for adhering non-plastic materials. Yet, the strength of the bond may vary depending on factors like surface preparation and environmental conditions during application, potentially requiring touch-up work or reinforcement for certain car dent repairs.

In the realm of auto repairs, both plastic welding and adhesive bonding offer effective solutions for structural integrity. Plastic welding excels in creating seamless bonds between similar plastics, ideal for intricate automotive components, while adhesive bonding provides a versatile, cost-effective alternative, suitable for a wide range of materials. When deciding between these methods for collision repair, consider the specific requirements of the job: plastic welding for complex, high-strength joints and adhesive bonding for faster turnaround times and cost savings on non-critical repairs. Ultimately, both techniques are game changers in modern auto restoration, enhancing safety and efficiency.