Plastic welding collision repairs offer a sustainable alternative to traditional metal welding, minimizing waste, energy consumption, and greenhouse gas emissions. Despite challenges like toxic substance concerns and energy usage, strict waste management and recycling can mitigate these issues. Future advancements in plastic welding collision techniques aim to increase durability, efficiency, and precision, leading to quicker turnaround times, less waste, improved structural integrity, and safer vehicles with minimal environmental impact.

“In the realm of sustainable repairs, plastic welding emerges as a game-changer for the automotive industry. This article explores how plastic welding, specifically tailored for collision repair, offers an eco-friendly alternative to traditional methods. We delve into the benefits and environmental advantages of this technique, examining its potential to reduce waste and minimize the carbon footprint. Furthermore, we look ahead to future prospects, highlighting advanced techniques that could further enhance sustainability in plastic welding collision repair.”

- Understanding Plastic Welding: A Sustainable Solution for Repairs

- The Environmental Impact of Plastic Welding in Collision Repair

- Future Prospects: Enhancing Sustainability through Advanced Plastic Welding Techniques

Understanding Plastic Welding: A Sustainable Solution for Repairs

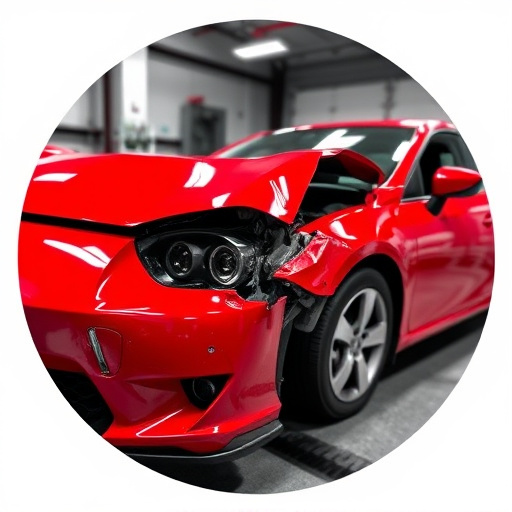

Plastic welding is a specialized technique that has gained significant attention as a sustainable solution for repairs, especially in the auto body shop industry. Unlike traditional metal welding, which can be energy-intensive and produce excessive heat, plastic welding focuses on bonding polymeric materials through controlled application of pressure and heat. This method is particularly useful for dent removal and vehicle restoration, offering an eco-friendly alternative to more destructive repair methods.

In the context of collision repair, plastic welding provides several advantages. It minimizes waste generation by preserving the original material, reducing the need for additional resources in re-creating damaged parts. Moreover, it facilitates faster repair cycles, contributing to reduced environmental impact through lower energy consumption and lesser greenhouse gas emissions when compared to conventional manufacturing processes. As such, plastic welding is not just a game-changer in auto body shops but also a key strategy for achieving sustainability in vehicle restoration efforts.

The Environmental Impact of Plastic Welding in Collision Repair

Plastic welding in collision repair has both environmental benefits and challenges. While it offers a sustainable solution by reducing waste and utilizing recycled materials, it also raises concerns about the ecological impact. The process involves the use of adhesives and fillers that can contain toxic substances, posing potential risks to air quality and water sources if not properly managed. Additionally, the energy consumption associated with plastic welding contributes to carbon emissions, counteracting some of the environmental advantages.

In the realm of car paint services and collision repair, balancing these factors is crucial. Body shop services that adopt plastic welding must implement stringent waste management protocols, including proper disposal and recycling practices. By doing so, they can minimize the ecological footprint, ensuring that their commitment to sustainable repairs translates into tangible positive changes in the environment.

Future Prospects: Enhancing Sustainability through Advanced Plastic Welding Techniques

The future of sustainable repairs lies in the hands of advanced plastic welding techniques. As the automotive industry shifts towards lighter and more environmentally friendly materials, plastic welding collision repair is becoming increasingly prominent. New methods are being developed to enhance the durability and eco-friendliness of these repairs, reducing waste and energy consumption associated with traditional manufacturing processes.

Imagine a collision center where dent removal is not just an art but a precise science, ensuring that every car bodywork service is executed with utmost care and efficiency. Through continued innovation in plastic welding technology, we can anticipate faster repair times, reduced material usage, and improved structural integrity. This not only benefits the environment but also contributes to safer and more reliable vehicles on the road.

Plastic welding offers a promising, sustainable approach to collision repair, reducing environmental impact by minimizing waste and energy consumption. As technology advances, we can expect even more efficient, eco-friendly plastic welding techniques to emerge, reshaping the industry’s landscape for a greener future. By embracing these innovations, professionals in the collision repair sector can contribute significantly to sustainability goals while ensuring high-quality repairs.