Plastic welding collision repair involves assessing damage, preparing surfaces, and choosing suitable methods like hot gas, ultrasonic, or laser welding for diverse plastics (polyester, polypropylene, ABS, polycarbonate) used in modern vehicles. Specialized knowledge, equipment (infrared heaters, ultrasonic machines), controlled conditions, and precise techniques ensure restored plastic components are aesthetically pleasing and structurally sound for safe driving.

After a collision, plastic welding is often crucial for restoring vehicles to their pre-accident condition. This process involves joining various types of plastics, each with unique properties. Understanding which plastics are weldable and mastering suitable techniques ensures structural integrity and aesthetic appeal. This article delves into the intricacies of plastic welding after collisions, guiding readers through common plastic types, welding techniques, and essential considerations for effective repairs.

- Understanding Plastic Welding After Collisions

- Common Types of Plastics for Collision Repair

- Techniques and Considerations for Plastic Welding

Understanding Plastic Welding After Collisions

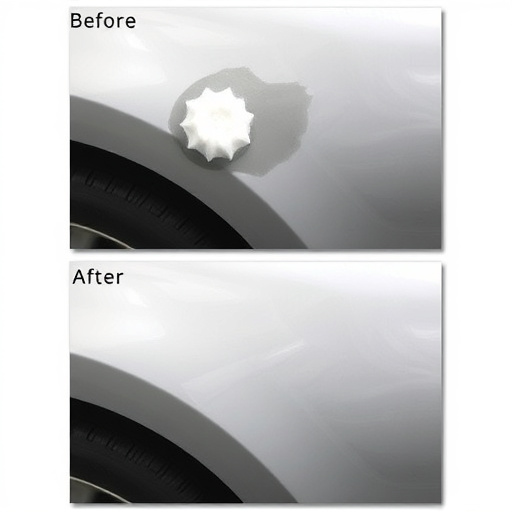

When a vehicle collides, plastic parts can be severely damaged. Understanding plastic welding collision repairs is crucial for efficient and effective restoration. In many cases, it’s possible to weld and repair cracked or broken plastic components, such as bumpers and other exterior panels, using specialized techniques tailored for these materials.

The process involves assessing the extent of damage, preparing the surfaces, and selecting the appropriate welding method. Common techniques include hot gas welding, ultrasonic welding, and laser welding, each offering distinct advantages for different types and sizes of plastic parts. An experienced auto body shop will have the tools and expertise to handle auto maintenance involving plastic welding, ensuring that repaired components not only look like new but also maintain structural integrity for safe operation on the road.

Common Types of Plastics for Collision Repair

In the realm of automotive collision repair, several types of plastics are commonly encountered, each presenting unique challenges and welding requirements. Polyester-based plastics, prevalent in older vehicle parts like fenders and door panels, offer a relatively straightforward welding process. Their ease of fusion makes them a preferred choice for quick repairs after a minor fender bender. Another widely used plastic is polypropylene, known for its versatility and availability in various automotive components, from bumpers to interior trim.

Modern vehicles often feature more complex designs with advanced engineering plastics such as ABS (Acrylonitrile Butadiene Styrene) and polycarbonate. These materials offer enhanced structural integrity and impact resistance but pose distinct welding challenges. Automotive body shops must employ specialized techniques and equipment for effective plastic welding, ensuring the restored vehicle bodywork is not only aesthetically pleasing but also structurally sound, ready to withstand future collisions.

Techniques and Considerations for Plastic Welding

Plastic welding after a collision requires specialized techniques due to the unique properties of plastics. Unlike metals, plastics don’t melt in the traditional sense; instead, they undergo a process known as polymerization or cross-linking, where molecular bonds are formed to fuse two pieces together. This makes plastic welding both an art and a science. The first step is identifying the type of plastic involved—there are numerous varieties, each with distinct chemical compositions and melt characteristics. Common types found in automotive parts include polyethylene (PE), polypropylene (PP), and ABS (Acrylonitrile Butadiene Styrene).

When welding plastics from a collision, several considerations come into play. Environmental factors like temperature and humidity can impact the bonding process. Thus, controlled conditions are crucial to ensure strong, durable welds. The use of specialized equipment, such as infrared heaters or ultrasonic welding machines, can facilitate this. Auto repair near me shops equipped with advanced plastic welding capabilities are better suited to handle complex repairs, ensuring components are not only functional but also structurally sound. Effective techniques might include using solvents to clean and prepare surfaces, applying primers to enhance adhesion, or employing robotic arms for precise, consistent welds—all tailored to the specific plastic types encountered in collision repair, like those found in a trusted automotive repair or collision repair center.

In conclusion, understanding the potential for welding plastics after a collision is key to effective automotive repair. By recognizing the compatibility of various plastic types and employing suitable welding techniques, professionals can ensure robust and lasting repairs. This process, involving precision and expertise, allows for the restoration of vehicles to their pre-collision condition, showcasing the versatility and significance of plastic welding in the industry.